Product Description:

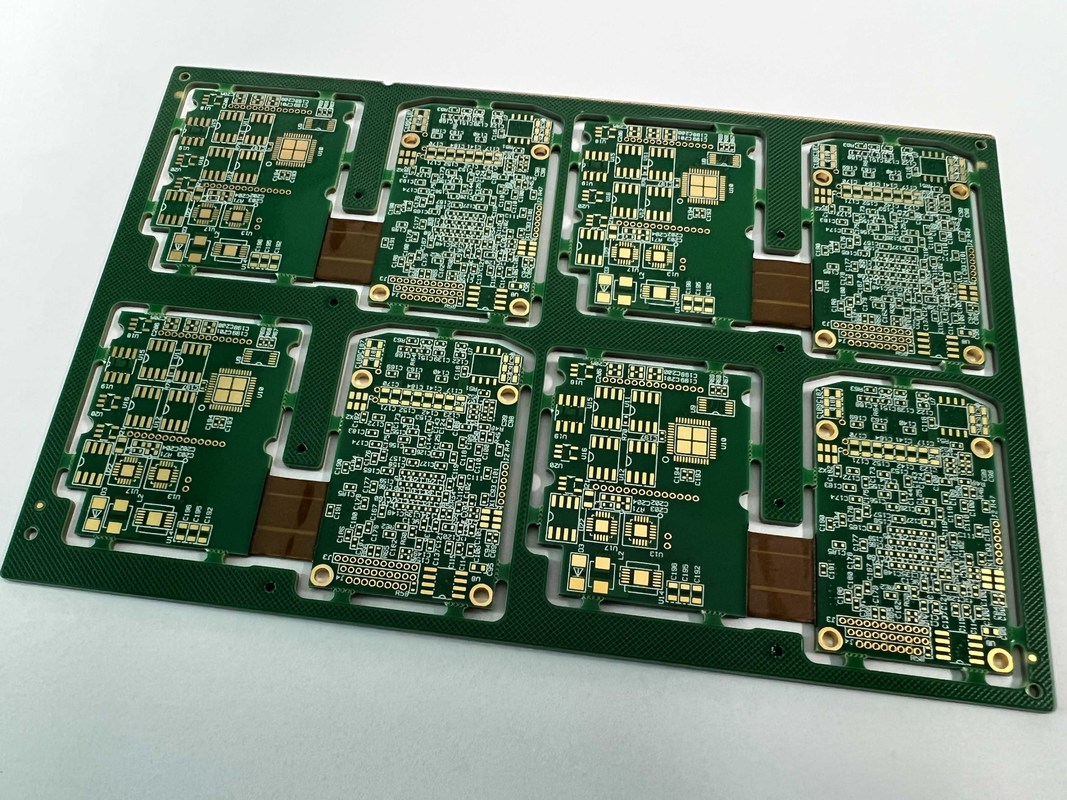

The Rigid Flex PCB, integrating the best attributes of both rigid and flexible circuits, offers an unrivaled level of design versatility and durability. This innovative solution is perfect for a wide range of applications that require the robustness of a rigid PCB combined with the adaptability of a flexible one. The Rigid Flex PCB is a quintessential example of a Flexible Printed Circuit Board - Rigid Flex, seamlessly blending rigidity where electronic components are mounted with the flexibility that allows the board to contour around corners and reduce space.

Flexibility is a key feature of the Rigid Flex PCB, with the ability to flex from 1 to 8 times. This adaptability makes it an excellent choice for devices that require the PCB to fit into tight or unconventional spaces, or where movement between different sections of the board is necessary. With a bend radius ranging from 0.5mm to 10mm, these boards can withstand repeated flexing without compromising the integrity of the electrical connections. This makes the Rigid Flex PCB an ideal solution for dynamic applications where movement can be a regular occurrence, such as in foldable or wearable technology.

Dimensions are critical in any PCB design, and the Rigid Flex PCB does not disappoint with a size of 41.55*131mm. This compact dimension allows for the incorporation of the Rigid Flex PCB into a wide array of products, from small handheld devices to larger, more complex machines. Despite its size, the design does not compromise on the level of detail or the number of features that can be included on the board. With a minimum trace/space of 0.1mm, the Rigid Flex PCB can support high-density designs, making it a perfect choice for sophisticated electronics where space is at a premium.

One of the most impressive technical specifications of the Rigid Flex PCB is its capability to accommodate a wide range of circuit complexities. Whether your project requires a simple, single-layer design or a complex, Multi-Layer Rigid and Flex Circuit Board, this product can be customized to meet your needs with anywhere from 1 to 28 layers. This level of versatility ensures that the Rigid Flex PCB can be tailored to the specific requirements of any application, whether it's for consumer electronics, medical devices, military systems, or aerospace technology.

The Rigid Flex PCB stands out as a Foldable Rigid-Flexible PCB, offering engineers and designers the creative freedom to develop innovative products that were previously unattainable with traditional PCBs. The ability to fold the PCB enables a new realm of product design possibilities, from smart devices with flexible displays to complex industrial machinery requiring intricate folding mechanisms. The robust construction paired with the flexible sections of the PCB means that these innovative designs do not have to sacrifice reliability for versatility.

In conclusion, the Rigid Flex PCB is a state-of-the-art Flexible Printed Circuit Board - Rigid Flex that pushes the boundaries of what's possible in electronic design. It combines the reliability of a rigid board with the adaptability of a flexible circuit, making it suitable for a myriad of cutting-edge applications. With dimensions tailored for compact spaces, an impressive range of possible layers, and the fine precision of its trace spacing, the Rigid Flex PCB is a true innovator in the PCB industry. Whether you are looking to create a Foldable Rigid-Flexible PCB or a Multi-Layer Rigid and Flex Circuit Board, this product has the features and capabilities to bring your most complex electronic designs to life.

Features:

-

Product Name: Rigid Flex PCB

-

Surface Finishing: HASL LF

-

Bend Radius: 0.5-10mm

-

Components: SMD, BGA, DIP, Etc.

-

Hole Position Deviation: ±0.05mm

-

No Of Layers: 4 Layer

-

Feature: Foldable Rigid-Flexible PCB

-

Feature: Flexible Printed Circuit Board- Rigid Flex

-

Feature: Multi-Layer Rigid and Flex Circuit Board

Technical Parameters:

|

Attribute

|

Specification

|

|

Material

|

FR4, Polyimide, PET

|

|

Dimension

|

41.55*131mm

|

|

Sanforized

|

Local High Density, Back Drill

|

|

No Of Layers

|

4 Layer

|

|

Product Type

|

PCB Assembly

|

|

Bend Radius

|

0.5-10mm

|

|

Surface Finishing

|

HASL LF

|

|

Flexibility

|

1-8 Times

|

|

Max Layer

|

52L

|

|

Profiling Punching

|

Routing, V-CUT, Beveling

|

Applications:

The

Flexible Rigid Printed Circuit Board (1)

, commonly known as Rigid Flex PCB, is a highly versatile product that finds application in a variety of scenarios, owing to its unique combination of rigidity and flexibility. This product is particularly useful in situations where the electronic circuit requires both stability and the ability to conform to different shapes. The Rigid Flex PCB is a hybrid construction, making it ideal for complex electronic applications.

A key application occasion for the Rigid Flex PCB is in aerospace technology, where the mix of rigid and flexible parts can be used to connect various components within a confined space. The flexible sections allow the board to bend during installation, fitting into tight spots without sacrificing the reliability provided by the rigid areas. Additionally, the

Multi-Layer Rigid and Flex Circuit Board (4)

variant with up to 52 layers offers unmatched complexity and density, which is perfect for advanced military and space applications where every inch of space counts.

Medical devices are another prime example of where the

Bendable Rigid-Flex PCB (2)

can be crucial. These products often require intricate designs that fit into irregular shapes, and the Rigid Flex PCB's ability to be shaped while maintaining a solid connection between components is invaluable. The use of biocompatible materials like Polyimide and PET ensures that these boards can be safely used in medical applications.

Consumer electronics, such as smartphones and wearable devices, also benefit from the space-saving features of the Rigid Flex PCB. The technology allows for a compact and efficient design, integrating multiple functions into one unit. Profiling methods like Routing, V-CUT, and Beveling make it possible to create precise shapes and contours, which are essential in the sleek designs of modern gadgets.

The Rigid Flex PCB is not just about versatility in design; it also provides a range of treatment options like ENIG, OSP, Immersion Gold/Tin/Silver to ensure excellent conductivity and longevity. These treatments also protect against environmental factors, which is crucial for outdoor applications such as drones or outdoor sensors.

In conclusion, the Rigid Flex PCB, with its robust FR4 material, precision profiling punching, and the ability to support complex, multi-layered designs, is a critical component in the design and manufacture of cutting-edge electronic devices across various industries. From aerospace to medical, consumer electronics to military applications, the Rigid Flex PCB offers the perfect balance between flexibility and strength, opening up new possibilities for product designers and engineers alike.

Customization:

Explore our Product Customization Services for the

Foldable Rigid-Flexible PCB

. Tailor your Rigid Flex PCB to fit your specific needs with dimensions precisely cut to 41.55*131mm. Our advanced manufacturing process allows for PCB layers customization ranging from 1-28 layers, ensuring versatility for various applications.

Our precision engineering guarantees a Hole Position Deviation of ±0.05mm, ensuring high-quality interconnections. Achieve intricate designs with our Minimum Trace/Space capability of 0.1mm, perfect for compact and complex electronics.

Designed to accommodate various bending needs, our

Flexible Printed Circuit Board- Rigid Flex

offers a Bend Radius of 0.5-10mm, providing durability and reliability for your foldable applications. Trust us to deliver a PCB that meets your exacting standards.

Support and Services:

Rigid Flex PCB products are designed to provide a robust and flexible solution for complex electronic circuitry. Our Product Technical Support and Services are committed to ensuring your Rigid Flex PCB meets your specific requirements and performs to the highest standards. We offer comprehensive support services which include:

Design Consultation:

Our team of experts is available to assist you with the initial design and layout of your Rigid Flex PCB, ensuring that it meets your functional requirements while adhering to manufacturing best practices.

Material Selection Guidance:

We provide advice on choosing the appropriate materials for your application to achieve optimal performance, reliability, and cost-effectiveness.

Prototyping Services:

To help you validate your design before full-scale production, we offer prototyping services that mirror our manufacturing process, ensuring a smooth transition to the final product.

Manufacturing Support:

Our state-of-the-art manufacturing facilities are equipped to handle both small and large volume production runs, with stringent quality control measures in place to ensure the highest quality of your Rigid Flex PCBs.

Testing and Quality Assurance:

We conduct comprehensive testing on all Rigid Flex PCBs, including electrical, thermal, and mechanical tests, to ensure that they meet all specifications and industry standards.

Technical Documentation:

Full documentation support is provided, including detailed assembly drawings, material lists, and test reports, to ensure you have all the information necessary for your application.

After-Sales Support:

Our commitment to our customers extends beyond the sale. We offer after-sales support to address any concerns or issues that may arise with your Rigid Flex PCB during its lifecycle.

Repair and Rework Services:

Should your Rigid Flex PCB require repair or rework, we offer services to quickly address and fix any issues, minimizing downtime and ensuring continued performance.

Our team is dedicated to providing you with the highest level of service and support for your Rigid Flex PCB needs. Contact us to learn more about how we can assist you with your project.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!